Discover the Latest Information on Copper Cathode Imports

By:Admin

Recently, [Company name] has made a significant impact in the market with its latest import of high-quality copper cathode. The copper cathode is a key raw material in the production of various products such as electrical wires, cables, and electronic devices. With the increasing demand for copper cathode in different industries, [Company name] has consistently demonstrated its ability to source and provide top-grade products to meet the needs of its clients.

The imported copper cathode by [Company name] meets stringent quality standards and is well-suited for diverse manufacturing processes. This latest import further strengthens the company's position as a reliable and competitive player in the global copper market. The company's commitment to sourcing superior quality copper cathode has earned it a strong reputation among its customers, who rely on [Company name] for consistent and high-quality supply.

[Company name] understands the importance of reliable and sustainable supply of copper cathode to its customers. As a result, the company has a strong emphasis on building strong and long-lasting relationships with its suppliers, ensuring a consistent supply of high-quality copper cathode to meet the demands of its clients. Through these efforts, [Company name] has become a trusted partner to many industries that depend on copper cathode for their manufacturing processes.

In addition to its import operations, [Company name] also prides itself on its strong commitment to sustainability and ethical sourcing practices. The company ensures that its supply chain adheres to the highest standards of environmental and social responsibility. By prioritizing sustainable sourcing, [Company name] aims to contribute to the overall well-being of the environment and the communities in which it operates.

The latest import of copper cathode by [Company name] is a testament to the company's dedication to providing top-grade products to its clients. The company's ability to consistently deliver high-quality copper cathode has positioned it as a leading supplier in the global market. With a strong focus on reliability, sustainability, and customer satisfaction, [Company name] continues to be a preferred choice for industries seeking a trusted and reputable supplier of copper cathode.

[Company name] looks forward to further expanding its reach and making a positive impact in the global copper market. With its strong commitment to quality, sustainability, and customer service, the company is well-equipped to meet the evolving needs of its clients and maintain its position as a key player in the import and distribution of copper cathode.

Company News & Blog

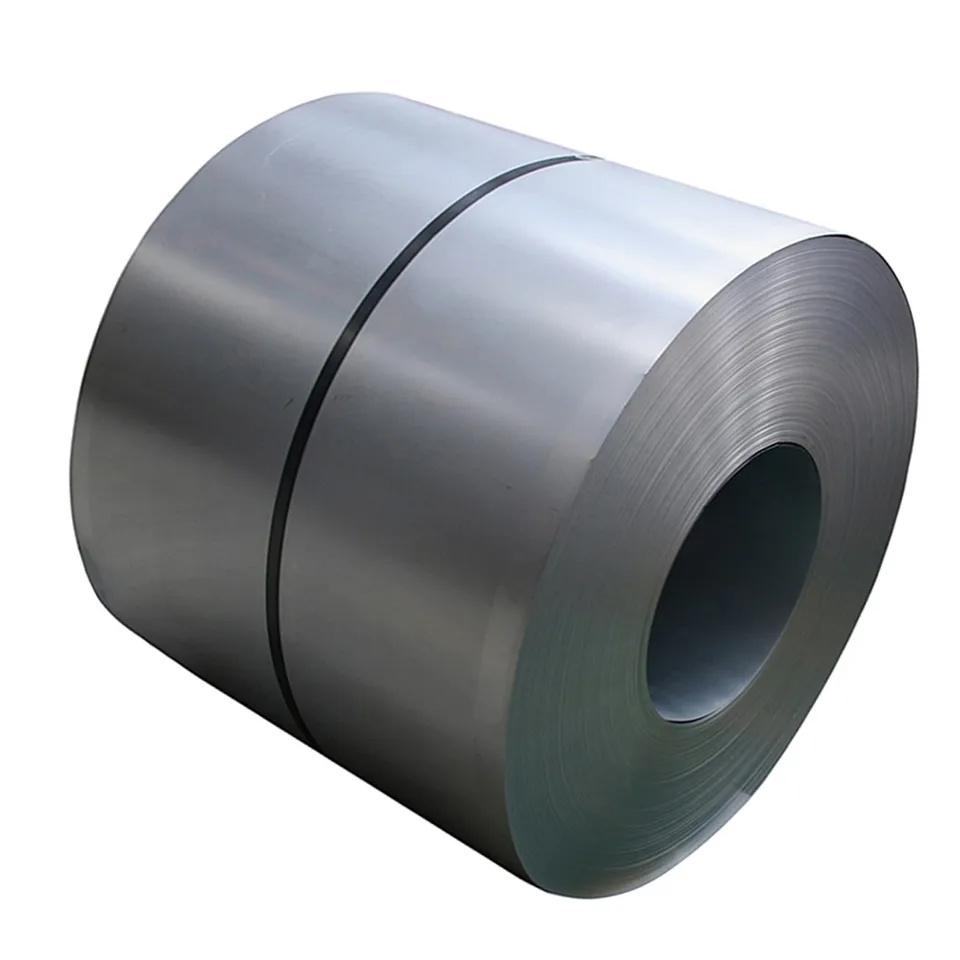

Durable and Versatile Cold Rolled Steel Sheets for Various Applications

Cold Rolled Steel Sheet, a high-quality steel product manufactured by a leading company in the steel industry, has become a popular choice for various applications. With its superior surface quality, excellent formability, and precise dimensional accuracy, Cold Rolled Steel Sheet has gained recognition for its exceptional performance in a wide range of uses, from automotive to construction and manufacturing sectors.The company behind the production of Cold Rolled Steel Sheet, {}, has been a key player in the steel manufacturing industry for several decades. With a strong commitment to innovation, quality, and customer satisfaction, {} has positioned itself as a trusted provider of advanced steel products.Cold Rolled Steel Sheet is manufactured using a cold reduction process, which involves passing the steel through a series of rollers at room temperature. This process results in a product with improved surface finish and tighter tolerances compared to hot rolled steel. The Cold Rolled Steel Sheet produced by {} is known for its smooth and clean surface, making it suitable for painting, plating, and other finishing processes.One of the key advantages of Cold Rolled Steel Sheet is its excellent formability. The material can be easily formed into various shapes, making it ideal for applications that require intricate designs and tight tolerances. Additionally, Cold Rolled Steel Sheet exhibits high strength and good weldability, allowing for the fabrication of strong and durable components.The dimensional accuracy of Cold Rolled Steel Sheet is another noteworthy feature. {} employs advanced manufacturing technologies and stringent quality control measures to ensure that the Cold Rolled Steel Sheet meets the specified thickness and width requirements. This precision and consistency make Cold Rolled Steel Sheet a preferred choice for parts and components that demand tight dimensional tolerances.In the automotive industry, Cold Rolled Steel Sheet is widely used for the production of vehicle components, such as body panels, chassis parts, and structural reinforcements. Its excellent surface quality and formability make it an ideal material for achieving the desired aesthetics and performance in modern automobiles.Furthermore, Cold Rolled Steel Sheet finds application in the construction sector for various structural and architectural purposes. Its strength, formability, and dimensional accuracy make it a suitable choice for building components, roofing, cladding, and other construction-related products.The manufacturing industry also benefits from the use of Cold Rolled Steel Sheet in the production of equipment, machinery, and consumer goods. The material's consistent quality and performance characteristics make it a reliable option for a wide range of manufacturing applications.As a leading manufacturer of Cold Rolled Steel Sheet, {} continues to invest in research and development to further enhance the properties and capabilities of this product. By leveraging its expertise and technological capabilities, {} is committed to meeting the evolving needs of its customers and delivering innovative solutions for various industries.In line with its dedication to sustainability and environmental responsibility, {} ensures that the production of Cold Rolled Steel Sheet complies with stringent environmental standards. The company prioritizes efficiency and resource conservation in its manufacturing processes, minimizing the environmental impact of its operations.With its exceptional surface quality, formability, and dimensional accuracy, Cold Rolled Steel Sheet from {} has cemented its reputation as a high-performance steel product. Whether in automotive, construction, or manufacturing applications, Cold Rolled Steel Sheet continues to demonstrate its value as a versatile and reliable material, meeting the diverse needs of industries worldwide. Through continuous innovation and a steadfast commitment to quality, {} remains at the forefront of providing advanced steel solutions to its customers.

Rusting Pipes pose health risk to homes and businesses

Galvanized steel pipes have been a popular choice among consumers for years, and have proved to be a reliable and effective material for plumbing and construction needs. However, with the introduction of new technologies and materials, the traditional appeal of galvanized pipes has been on the decline. Despite this, one company is still committed to providing customers with high-quality galvanized steel pipes that are both durable and cost-effective.For over two decades, {!Company Name!} has been manufacturing and supplying galvanized pipes to the construction and plumbing industries. Established in 1999, the company has built a reputation for delivering premium quality products that meet the demands of customers across various sectors.While many in the industry have moved towards using plastic pipes and other alternatives, {!Company Name!} has continued to focus on galvanized steel pipes, citing their resilience and durability as primary reasons for their continued use.According to a company spokesperson, "Despite the availability of other alternatives, galvanized steel pipes continue to be the preferred choice for many customers. Unlike plastic pipes which can become brittle and crack over time, galvanized pipes can last for decades without needing replacement."Additionally, galvanized pipes offer better protection against corrosion, making them ideal for use in environments where exposure to moisture and other elements can cause deterioration. In particular, galvanized pipes are commonly used in applications where water is present, such as plumbing systems and outdoor applications like irrigation systems.The benefits of galvanized steel pipes extend beyond their durability and protective qualities. They are also readily available and cost-effective compared to other materials. With their ease of installation and reliability, galvanized pipes continue to be an efficient option for customers seeking cost-effective solutions for their plumbing and construction needs.However, {!Company Name!} understands the importance of continuously improving and innovating their products, and has recently announced the launch of a new line of galvanized steel pipes that offer even greater durability and protection against corrosion.“Our new range of galvanized pipes has been specifically designed for use in harsh and demanding environments,” said the company spokesperson. “We’ve incorporated advanced coating technologies that offer better protection than traditional galvanized pipes, making them ideal for use in applications like industrial and agricultural settings.”The new pipes will feature a thicker coating of zinc, which offers more robust protection against rust and corrosion. Additionally, the pipes will be available in various thicknesses, making them suitable for a range of applications.The company expects the new line of galvanized pipes to be well received by customers across various industries. With their enhanced protection and durability, the pipes provide an ideal solution for those seeking a durable and cost-effective option for their plumbing and construction needs.In conclusion, despite the availability of newer materials and technologies, galvanized steel pipes continue to be a popular choice for customers across various industries. With their resilience, durability, and cost-effectiveness, they offer a reliable solution for plumbing and construction needs. {!Company Name!} has been a key player in providing high-quality galvanized pipes for over two decades and continues to innovate its products to meet the changing demands of customers. With the launch of their new range of pipes, the company is poised to remain a leader in the industry and continue providing top-quality products to meet the needs of its customers.

Top Steel Bar Options for Construction Projects

[Company Introduction]{Steel Bar Company} is a leading manufacturer and supplier of high-quality steel bar products. With a commitment to innovation and customer satisfaction, {Steel Bar Company} has been serving various industries such as construction, automotive, manufacturing, and infrastructure development for over two decades. The company has garnered a reputation for delivering reliable and durable steel bar solutions to meet the ever-changing demands of the market.[News Content]The steel industry plays a crucial role in driving the global economy, and companies like {Steel Bar Company} are at the forefront of ensuring the supply of top-notch steel bar products. Recently, {Steel Bar Company} unveiled its latest line of steel bar products that promise to deliver unparalleled performance and reliability.The new line of steel bars, which comes in various shapes and sizes, is a testament to {Steel Bar Company}'s commitment to innovation and excellence. These steel bars are manufactured using advanced technology and superior quality raw materials, ensuring that they meet the highest industry standards. Whether it's for construction projects, automotive components, or general engineering applications, {Steel Bar Company}'s steel bars are designed to meet the diverse needs of its customers.One of the key features of the new steel bar products is their exceptional strength and durability. The bars are specifically engineered to withstand heavy loads and harsh environmental conditions, making them ideal for use in demanding applications. Additionally, {Steel Bar Company} has incorporated corrosion-resistant properties into the steel bars, further enhancing their longevity and performance. This is a crucial factor, especially for construction and infrastructure projects where the longevity of materials is a top priority.In addition to their superior quality, {Steel Bar Company}'s new steel bars are also designed to offer ease of use and versatility. The company has developed a range of steel bar solutions that can be readily customized to meet specific customer requirements. Whether it's cutting, bending, or welding, the steel bars can be easily manipulated to fit various project specifications, making them a practical choice for a wide range of applications.Moreover, {Steel Bar Company} is dedicated to sustainability and environmental responsibility. The manufacturing process of the steel bars adheres to strict environmental standards, ensuring minimal environmental impact. The company is also committed to ethical sourcing of raw materials, promoting responsible practices within the industry.The launch of the new line of steel bars is a clear reflection of {Steel Bar Company}'s ongoing efforts to stay ahead of the curve in the steel industry. By continually investing in research and development, the company aims to provide its customers with cutting-edge solutions that address their evolving needs. The introduction of these new steel bars further solidifies {Steel Bar Company}'s position as a trusted partner for businesses seeking high-quality steel products.In conclusion, {Steel Bar Company}'s unveiling of its latest steel bar products is a significant development that underscores the company's dedication to excellence and innovation. With a focus on quality, sustainability, and customization, {Steel Bar Company} continues to set the benchmark for superior steel bar solutions in the industry. As the global demand for steel products continues to grow, {Steel Bar Company} is well-positioned to meet the needs of its diverse customer base with its state-of-the-art steel bar products.

Top Quality Rebar Tying Wire for Construction Projects

Rebar Tying Wire Now Available from Leading Construction Supplies CompanyAs the construction industry continues to evolve and adapt to new technology and materials, there is an increasing demand for high-quality construction supplies. One essential product that has become integral to the construction process is rebar tying wire, which is widely used for securing reinforcing steel bars in concrete structures. With the growth of the construction industry, the need for reliable and efficient rebar tying wire has become more pronounced.In response to this demand, {Company Name}, a leading supplier of construction supplies, is now offering a wide range of rebar tying wire products to meet the needs of the construction industry. With a strong commitment to providing the highest quality materials and excellent customer service, {Company Name} has become a trusted name in the construction supplies market.{Company Name} was established with the goal of providing construction professionals with access to the best and most reliable products on the market. Over the years, the company has built a solid reputation for delivering top-quality construction supplies, including rebar tying wire, at competitive prices. With a strong focus on customer satisfaction, {Company Name} has developed a loyal customer base and continues to expand its product offerings to meet the evolving needs of the construction industry.The rebar tying wire available from {Company Name} is manufactured to the highest standards, ensuring durability and reliability in a variety of construction applications. Whether used for securing concrete reinforcement in building foundations, road construction, or infrastructure projects, {Company Name}'s rebar tying wire is designed to provide superior performance and ease of use.In addition to their commitment to quality, {Company Name} also places a strong emphasis on sustainability and environmental responsibility. The rebar tying wire offered by {Company Name} is produced using eco-friendly manufacturing processes, minimizing environmental impact while providing construction professionals with a sustainable and reliable product.One of the key advantages of {Company Name}'s rebar tying wire is its versatility. Available in various gauges and lengths, the rebar tying wire can be customized to suit the specific needs of a wide range of construction projects. This flexibility ensures that construction professionals can access the right materials for their unique requirements, improving efficiency and productivity on the job site.Furthermore, {Company Name} is committed to providing exceptional customer service and support. With a team of knowledgeable and experienced professionals, the company is able to offer expert advice and guidance to construction professionals, ensuring that they have access to the best products for their projects. From product selection to delivery and after-sales support, {Company Name} is dedicated to providing a seamless and reliable experience for its customers.In conclusion, the availability of high-quality rebar tying wire from {Company Name} represents a significant advancement for the construction industry. With a strong emphasis on quality, sustainability, and customer satisfaction, {Company Name} is well-positioned to meet the growing demand for reliable construction supplies. By offering versatile and durable rebar tying wire, {Company Name} is empowering construction professionals to achieve superior results on their projects while contributing to a more sustainable and efficient construction industry.

Discover the Latest Developments in Copper Foil - Find out Why It's Making Waves in the Industry

Title: Innovations in Copper Foil Manufacturing Revolutionize Electronic IndustryIntroduction:In an era where technological advancements are rapidly transforming the global market, copper foil continues to play a critical role in the electronic industry. As a key component in electronic devices, it serves as the foundation for printed circuit boards (PCBs) and provides essential conductivity and durability. Recognizing the importance of this versatile material, several companies, including a leading manufacturer, have made significant advancements to provide high-quality copper foil solutions. This article explores the latest innovations in copper foil manufacturing and their impact on the electronic industry.Paragraph 1:Copper foil has long been a staple in the production of electronic devices due to its excellent electrical conductivity and heat dissipation properties. Its ability to efficiently transmit electrical signals makes it indispensable in PCBs used in smartphones, tablets, laptops, and other consumer electronics. As the demand for smaller, lighter, and more efficient devices increases, manufacturers are constantly seeking ways to enhance the performance and reliability of copper foil.Paragraph 2:One industry leader in copper foil manufacturing, [Company Name], has recently introduced a groundbreaking manufacturing process that sets a new standard for the industry. The company has developed a unique method that enables the production of ultra-thin copper foils without compromising its electrical conductivity and mechanical strength. This advancement allows for the creation of even more compact electronic devices without sacrificing performance.Paragraph 3:Compared to traditional copper foils, the newly developed ultra-thin copper foils offer several benefits. Firstly, they enable manufacturers to create thinner and more flexible PCBs, making them suitable for a variety of applications, including curved or foldable devices. This flexibility opens up possibilities for innovative designs and enhanced product aesthetics.Paragraph 4:Furthermore, the superior electrical conductivity of the advanced copper foils translates into improved device performance. With lower electrical resistance, electronic signals can travel more efficiently, leading to enhanced speed, reduced power consumption, and increased overall functionality of electronic devices. These advancements contribute to the seamless integration of copper foils in modern electronic designs, ensuring optimal performance in a variety of applications.Paragraph 5:Additionally, the durability and reliability of copper foils have been enhanced through another breakthrough introduced by [Company Name]. By developing an innovative surface treatment technique, the company has created copper foils with increased resistance to oxidation and corrosion. This ensures a longer lifespan and improved stability of electronic devices, irrespective of environmental conditions, thus reducing the risk of performance degradation or failure.Paragraph 6:The implementation of these innovative copper foil manufacturing technologies not only benefits electronics manufacturers but also adds value to end-users. Consumers can expect products with improved performance, durability, and longevity, making their investment in electronic devices more worthwhile. Moreover, the advancements in copper foil manufacturing contribute to a more sustainable future as thinner foils result in reduced material consumption and waste generation during the production process.Conclusion:The developments pioneered by [Company Name] in copper foil manufacturing mark a significant milestone in the electronic industry. As technology continues to evolve, the demand for more advanced and efficient electronic devices will persist. By providing ultra-thin copper foils, with unparalleled electrical conductivity, flexibility, and durability, [Company Name] is driving innovation and shaping the future of the electronic industry. These groundbreaking advancements hold the promise of powering the next generation of electronic devices and revolutionizing the way we interact with technology.

High-quality copper cathode imports surge in response to increasing demand

[Company Name], a leading company in the metal and mining industry, has recently announced the import of a large quantity of copper cathode. This move comes as part of the company's ongoing efforts to expand its portfolio and provide high-quality metal products to its customers.Copper cathode is a primary raw material in the production of copper products and is widely used in various industries such as construction, electrical, and automotive. With the increasing demand for copper cathode in the global market, [Company Name] has seized the opportunity to import a significant amount of this essential material.The imported copper cathode meets the highest international standards and has undergone rigorous quality control checks to ensure its purity and quality. By importing high-quality copper cathode, [Company Name] aims to strengthen its position as a reliable supplier of metal products in the market.With an extensive network of suppliers and partners, [Company Name] has established itself as a trusted name in the metal and mining industry. The company's commitment to providing top-notch products and services has earned it a strong reputation in the global market. By importing copper cathode, [Company Name] seeks to further enhance its standing and meet the growing needs of its customers.In addition to importing copper cathode, [Company Name] also produces a wide range of metal products, including copper rods, aluminum ingots, and zinc sheets. These products are widely used in various industrial applications and have earned recognition for their superior quality and performance.[Company Name] is known for its dedication to innovation and sustainability in the metal and mining industry. The company invests in advanced technologies and processes to ensure efficient production and minimize its environmental impact. With a strong focus on sustainability, [Company Name] is committed to meeting the needs of its customers while promoting responsible and ethical practices in its operations.The import of copper cathode by [Company Name] is a testament to the company's strategic vision and its ability to adapt to market trends. By diversifying its product portfolio and sourcing high-quality materials, [Company Name] aims to stay ahead of the competition and continue to meet the evolving needs of its customers.As a part of its expansion plans, [Company Name] is also exploring new market opportunities and partnerships to further strengthen its presence in the metal and mining industry. With a solid foundation and a clear direction, the company is well-positioned to achieve its long-term goals and maintain its leadership in the global market.The import of copper cathode by [Company Name] is a significant development that underscores the company's commitment to providing top-notch metal products to its customers. With a strong focus on quality, sustainability, and innovation, [Company Name] is poised to remain a leading player in the metal and mining industry for years to come.

Why the Demand for Recycled Copper is Soaring in the Market

article.Scrap copper market gains traction due to rising demandThe global scrap copper market is witnessing a surge in demand, driven by increased usage in the manufacturing of electrical equipment and construction activities. Copper, one of the most widely used industrial metals, is highly valued for its conductivity, ductility, and resistance to corrosion. However, the extraction of primary copper ore is a costly and energy-intensive process, making the recycling of scrap copper an attractive alternative for sustainable production. Scrap copper can be extracted from various sources, including old wires, cables, pipes, and appliances, and can be sold for profitable returns.In response to the growing demand for scrap copper, many companies are offering specialized services in the collection, processing, and trading of copper scrap. One such company is {remove brand name}, a leading player in the scrap metal industry. With over {remove specific number} years of experience, {remove brand name} has established a reputation for providing reliable and efficient scrap metal solutions to customers in the {remove region} region.{Remove brand name}'s services include the collection and transportation of scrap metal from various sources, such as demolition sites, construction sites, manufacturing plants, and residential areas. The collected scrap is then sorted and processed in {remove brand name}'s state-of-the-art facilities, using advanced techniques like shearing, shredding, and granulation. These processes ensure that the scrap is segregated according to its grade, size, and purity, and is free from any contaminants that may affect its quality.Once the scrap copper is processed, it is sold to various buyers in the domestic and international markets. {Remove brand name} has a strong network of buyers, including foundries, smelters, refiners, and exporters, who use the scrap copper as a raw material for their operations. The demand for scrap copper in these markets is largely driven by the need to reduce the dependence on primary copper ore, which is becoming scarcer and costlier to mine.{Remove brand name} has also adopted sustainable practices in its operations, such as the use of renewable energy sources, the reduction of waste generation, and the promotion of responsible sourcing. These initiatives have not only reduced the environmental impact of {remove brand name}'s operations but have also improved its social and economic performance, by creating jobs and supporting local communities.In conclusion, the rising demand for scrap copper is a testament to its importance in modern industrial processes and the need for sustainable production. Companies like {remove brand name} have played a vital role in promoting the recycling of scrap copper and offering efficient solutions to customers. As the demand for scrap copper continues to grow, it is expected that more players will enter the market and innovate to meet the evolving needs of the industry.

Discover the Advantages of HRB400E and HRB500E Rebar for Superior Construction Strength

In recent news, high-strength steel rebar products have been making waves in the construction industry. Steel manufacturers have been innovating their products to provide stronger and more durable materials for building structures. One of the products that have caught the attention of developers and contractors is the HRB400E and HRB500E rebar.HRB400E and HRB500E are both high-strength steel rebar products designed to withstand heavy loads and stresses. These rebar products are manufactured using advanced technology and are engineered to meet strict quality standards. They are made of low carbon steel, which gives them high elasticity and ductility, making them ideal for high-rise buildings, bridges, and other large-scale constructions.Developers and contractors who utilize HRB400E and HRB500E rebar can be assured that the materials they are using have undergone strict quality control measures. The rebar products are tested for tensile strength, elongation, yield strength, and other mechanical properties. This ensures that the materials can withstand the impact of natural disasters such as earthquakes and typhoons.Moreover, HRB400E and HRB500E rebar products have a robust corrosion resistance capacity, which can help prevent degradation over time, reducing the need for continuous maintenance. The rebar's strength and durability can also help to reduce the overall cost of construction as using stronger materials can lead to the reduction of the amount of steel used in construction, as well as a decrease in the number of reinforcements needed.One company that produces high-quality HRB400E and HRB500E rebar products is {Company Name}. {Company Name} is a reputable steel manufacturer known for its innovative techniques in the production of steel products. {Company Name} is dedicated to providing quality materials for construction projects while ensuring their products meet the most stringent quality standards.At {Company Name}, the manufacturing process of HRB400E and HRB500E rebar is carefully monitored from start to finish. Quality control measures are put in place to ensure that the materials' tensile strength, elongation, yield strength, and other mechanical properties meet the expectations of developers and contractors.Moreover, {Company Name} uses advanced technology to manufacture its products, ensuring that they remain competitive in the market. The company has also invested in a state-of-the-art R&D center, where new products are developed and tested. This helps to ensure that {Company Name} stays ahead of the competition by producing innovative and cutting-edge products that meet the needs of the construction industry.{Company Name} has an extensive portfolio of clients who rely on the company's products for their construction projects. With a dedicated and skilled workforce, the company has been able to maintain its position as a leading steel manufacturer, providing high-quality products to customers worldwide.In conclusion, HRB400E and HRB500E rebar products are making waves in the construction industry, providing developers and contractors with durable and robust materials for their projects. Manufacturers like {Company Name} have been at the forefront of the production of high-strength steel products, utilizing innovative technology to produce materials that meet the most stringent quality standards. With this commitment to quality and innovation, {Company Name} continues to provide excellent products to customers worldwide while remaining competitive in the market.

High-quality Hot Rolled Steel Sheet In Coils Available Now

[Company Name] is proud to announce the launch of its new product, Hot Rolled Steel Sheet in Coils. This latest addition to our product line is a result of our continuous effort to expand and improve our offerings to meet the growing needs of our customers.Hot Rolled Steel Sheet in Coils is a versatile and widely used product in various industries such as construction, automotive, manufacturing, and infrastructure. It is made by passing the steel through a series of rollers at high temperatures, which results in a product that is strong, durable, and highly malleable. Our Hot Rolled Steel Sheet in Coils is available in a variety of thicknesses and widths to suit the specific requirements of our customers.One of the key features of our Hot Rolled Steel Sheet in Coils is its superior surface quality. The product has a smooth and uniform surface, free from any defects or imperfections, making it suitable for a wide range of applications. Additionally, it offers excellent formability and weldability, allowing for easy shaping and joining during the manufacturing process.In addition to the superior quality of our Hot Rolled Steel Sheet in Coils, [Company Name] also offers exceptional customer service and support. Our team of experienced professionals is dedicated to providing personalized solutions to meet the unique needs of each customer. From product selection to delivery, we strive to ensure a seamless and efficient experience for our clients.Furthermore, [Company Name] is committed to sustainability and environmental responsibility. Our Hot Rolled Steel Sheet in Coils is manufactured using eco-friendly processes and materials, adhering to the highest industry standards for environmental protection. With a focus on reducing our environmental footprint, we aim to provide our customers with products that are both high-performing and sustainable.As a leading supplier of steel products, [Company Name] takes pride in its state-of-the-art manufacturing facilities and advanced technology. Our production process is designed to ensure the highest level of quality and consistency in every batch of Hot Rolled Steel Sheet in Coils. With stringent quality control measures in place, we guarantee that our products meet or exceed the industry standards for performance and durability.The launch of Hot Rolled Steel Sheet in Coils is a testament to [Company Name]'s commitment to innovation and continuous improvement. By introducing this new product, we aim to offer our customers a comprehensive range of high-quality steel products to support their diverse needs. Whether it is for construction projects, automotive parts, or other applications, our Hot Rolled Steel Sheet in Coils is a reliable choice for professionals and businesses alike.In conclusion, [Company Name] is excited to introduce Hot Rolled Steel Sheet in Coils as the latest addition to our extensive product portfolio. With its exceptional quality, versatility, and environmental sustainability, this new product is set to make a positive impact in various industries. As we continue to uphold our commitment to excellence, we are confident that our Hot Rolled Steel Sheet in Coils will be well-received by our customers and partners. For more information about this product and our comprehensive range of steel solutions, please contact us [here].

How to Choose the Best Corrosion-Resistant Steel Tube for Your Needs

Stainless Steel Tube Company Plans Expansion to Meet Growing DemandStainless Steel Tube, a global leader in the production of high-quality stainless steel tubing, has announced that it will be expanding its operations in response to growing demand for its products. The company has been experiencing steady growth over the past few years, and this expansion will allow it to continue meeting the needs of its customers worldwide.Founded in the early 2000s, {insert company introduction} The company has become known for its commitment to quality and its ability to produce stainless steel tubing that meets the unique needs of a variety of industries. Its products are used in everything from medical equipment to aerospace engineering, and the company has established a reputation for excellence in both product quality and customer service.The decision to expand comes as the demand for stainless steel tubing continues to grow. With an increase in applications across a range of industries, the company has been experiencing a surge in orders from both existing and new customers. By expanding its operations, Stainless Steel Tube will be able to meet this increased demand and continue to provide its customers with the quality products and service they have come to expect.The expansion will involve the construction of a new manufacturing facility, which will be equipped with the latest technology and equipment to ensure that the company can continue to produce tubing of the highest quality. It will also create new job opportunities in the local area, helping to support the region's economy."We are thrilled to announce our expansion plans," said the company's CEO. "We are committed to meeting the needs of our customers, and this expansion will allow us to continue doing so. With the latest technology and equipment, we will be able to produce even better products and provide an even higher level of service to our customers."The expansion is expected to be completed within the next two years, and the company is already planning for the future. It is investing in research and development to ensure that it stays at the forefront of the industry and can continue to meet the evolving needs of its customers.Stainless Steel Tube has always been committed to sustainability, and this commitment will be carried forward into the new facility. The company will focus on reducing its environmental footprint through energy-efficient practices and the use of recycled materials."We are proud of our commitment to sustainability and will continue this focus as we expand," said the CEO. "We believe that it is important to operate in an environmentally responsible way, and the new facility will reflect this commitment."Overall, the expansion will allow Stainless Steel Tube to continue to grow and expand its reach, providing its customers with the high-quality tubing they need to succeed. With a focus on innovation and sustainability, the company is well-positioned to continue its success into the future.